|

|

|

|

|

| Products Show |

Flotation Equipments

1XJ type flotation(model A) belongs to the self-suction mining flotation with the air of converying rotor; it is applicable to the works in roughing, cleaning, scavenging and reversing flotation of the black metals such as iron and the color metals and the nonmetal material such as copper, lead, zinc, molybdenum and gold etc. But it is not suitable to work of roughing and scaverying of large flotation factory.

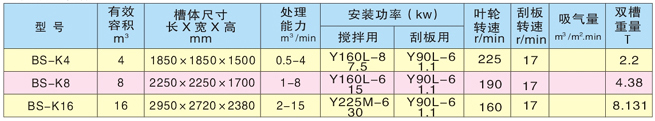

Main Technique Parameters

|

2BS-K type flotation belongs to the Inflated flotation with deep grooves. It function of the rotor is mixing mine and dispersing air; so the damageable parts are not worn out easy. Its power is more economic than other flotation. This machine dont have self-suction function, so it need step disposition and foam pump during the operation.

Main Technique Parameters:

|

3SF type flotation is double-function mechanical mixing flotation with spontaneously aerated and slurry self-priming. It adopts forward-type groove with novel structure, double-vane water turbine, diversion kerb tube and dummy bottom device, mine in the groove is fixed in flow type, double loop, it is beneficial to suspend of coarse mineral.

SF type and JJF type can be configured into a combined unit, SF as a inhale groove, JJF as direct-current groove , whole combined unit should be installed horizontally. |

Features of Equipment

large quantity of inspiratory capacity it improves by 50% comparing type A

nergy savingit can reduce 11% comparing to type A

air dispersing well

starting with load

simple structure, easy repairing |

|

Main Technique Parameters:

|

4Type JJFII is an imitation one of American Wim branch flotation which belongs to spontaneously aerated mechanical flotation. It uses deep-type rotor, shapes like stars, the vane gets radial symmetry and the stator is canister. It adds the draft tube and dummy bottom under the rotor, so it can make cycle of mine under the groove avoiding the mine sinking in the groove. It is suitable to select the nonferrous metal, ferrous metal and nonmetallic minerals.

Features of Equipment

large quantity of inspiratory capacity

ow consume energy--- saving 20%-30%comparing type A

air dispersing well

wear resistance and low maintenance costs

starting with load

less medicinal preparations consuming

simple structure, easy repairing

Advanced mine control system, convenient to operate and manage

a listening mine groove is designed in this flotation, so the working progress is horizontal positioning and saving foam pump.

Main Technique Parameters:

|

Main Technique Parameters of XJZ Type Flotation

|

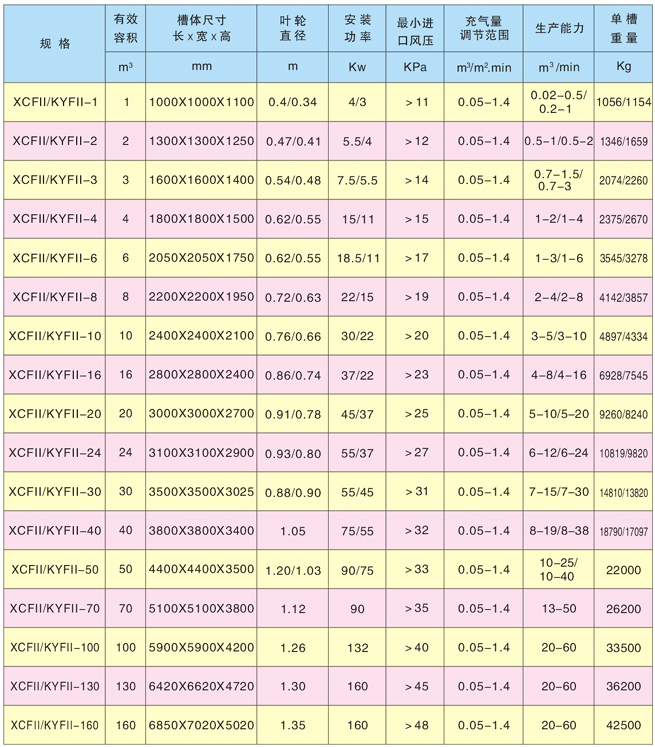

5Type XCFII is a concurrent flofation with mechanical agitator, its advantages are the same as general concurrent flofation, also can self-prime ore ( ore inletting ) and mine ( returnning) without foam pump, but the power consumption is a little higher than type KYF.

6Type KYFII is a concurrent flofation with mechanical agitator but with the function of self-mine, the power is a little lower. If this machine is selcted in the flotation process, the equipment needs stepping allocation and the mine returnning needs foam pump. To achieve the level configuration requirements of flotation equipment, we can combine type XCFII and type KYFII, XCFII type as inhalation slot, KYFII type as the DC slot, which can eliminate foam in mine returnning. It shows the unique performance of each model, The structure feature of this floatation is setting abackward blade with a double down the hammer-shaped impeller, and setting an air distributorin the centerof rotor,so it has? Excellent performance comparing the similar floatation. |

Features of Equipment

1low consume energy

2air dispersing well

3rotor acts as a centrifugal pump that can make the solid remain afloat in the groove.

4wear resistance and low maintenance costs

5starting with load

6less medicinal preparations consuming

7simple structure, easy repairing

8U-shaped groove can reduce short-circuit, more convenient.

9Advanced mine control system, convenient to operate and manage

10combined type SCF and type KYF that make the working progress in horizontal positioning and save foam pump. |

Main Technique Parameters

|

7BF type flotation is a flotation with mechanical agitator. Its rotor is made of closed double-cut hammer that can make powerful mine circulation. It is suitable for separating nonferrous metal, ferrous metal, nonmetallic minerals and chemical industrial material and recycling useful mineral. that can make powerful mine circulation. It is suitable for separating nonferrous metal, ferrous metal, nonmetallic minerals and chemical industrial material and recycling useful mineral.

Features of Equipment

1Large inspiratory capacity and low-power

2Every groove has three functions assuction, suction pulp and flotation, thus it can? form a flotation circuit without any auxiliary equipment. Level setting is,easy to change the process

3Reasonable pulp cyclec can minimize sedimentation of sand

4Setting the mine control system and electric control device, convenient to adjust

Main Technique Parameters: of BF Type Floatation

8KS.1/II flotation machine is inflatable mechanical raking flotation machine. It is on the basis of a large number detail analysis of flotation machine, and it is the successful development of advanced flotation device by industry practice. The KS.1 has the capacity of absorbing pulp, it can be the suction tank in beneficiation process. It has below features:

Low air consumption, the air consumption reduces when tank depth increase.

High bubble utilization, deeper the tank and more bubble time in tank, so the collision opportunity between the bubble and the mineral granule.

Because of the high quality of concentrate and high recovery, it is easy to form stable bubble zone and long separation zone,? it will can improve the useful elements recovery and concentrate quality.

Reduce the construction area because the floatation machine is small footprint.

Reduce the construction area because the floatation machine is small footprint.

Save energy 4-5%, and save wearing parts 50-70%.

Main Technique Parameters:

|

9.GF type flotation machine is the self-absorbing pulp and self-absorbing air mechanical raking flotation machine. It is suitable for the small and medium factories to select non-ferrous metal, black metal, precious metal and non-metallic mineral. The particle size range <0.074MM, the pulp density <45%

Features of Equipment

1Self-absorption air-----can reach 1.2 .min.

2Self-absorption pulp-----can absorb mineral and bubble mineral by itself, the floatation process can be configurate flatly

3Good pulp circulation, stable fluid level-----in the tank pulp will not whirl and jump.

4High select efficiency-----improve the recovery of rough grain and fine mineral.

5Low power----save 15-20% energy compared with other type floatation machine, but can absorb enough air and pulp.

6Long life of the wearing parts------especially the life of the impeller and stator will be twice as other type floatation machines.

Main Technique Parameters:

|

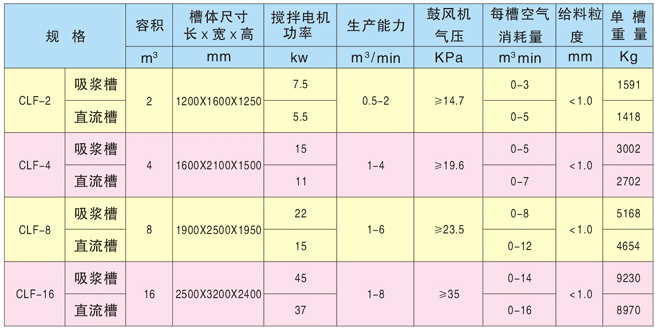

10CLF type coarse-grained flotation belongs to Inflatable mechanical mixing flotation. Its rotor adopts a high specific speed backward blades, the shapes of the under vane are designed the same as thestreamline with the mine passing vane. Thus it has the advantages of low agititor, large recycling capacity of mine and low power. So larynx together with gratings that can fully guarantee the suspension of coarse mineral and scattering of the air. Gratings can make short rising distance of mining bubble of coarse mineral, so it stays in shallow floatation state, reduces turbulence of upper zone slurry tanks ,thus setting a stableSeparation and foam layer.

The machine has absorption tanks and it can Self-priming feeder and foam Mineral from outside. So the floatation working can level processing but inflation requires extra fans. It is mainly used for coarse mineral which the conventional flotation cant, of course it also for conventional flotating. It is suitable to the Sorting working of color metals , black metals and nonmetallic minerals.

Features of Equipments

big granularity of mineral processing----the Maximum granularity of mineral can reaches 1mm

setting gratings in inner tank---- make the pulp have smooth surface , Improve technical performance

large quantity of air inflation capacity , air dispersing well and lower power

goodpulp circulation----unsinkable slot when processing coarse minerals

set mine control system, convenient to operate and manage

coarse minerals flotation setting absorption tank-- the working progress is horizontal positioning and saving foam pump

Main Technique Parameters:

|

|

|

|

|

|

COPYRIGHT (C) 2011 www.zjkuangji.com all RIGHTS RESERVED

AddressNo.23, Dahao Road, Huandong Street, Zhuji City, Zhejiang Province, China.

Tel0575-87091276 Fax0575-87092340 E-Mailwebmaster@zjkuangji.com |

|

|

|